- Our pursuit of higher quality products.

-

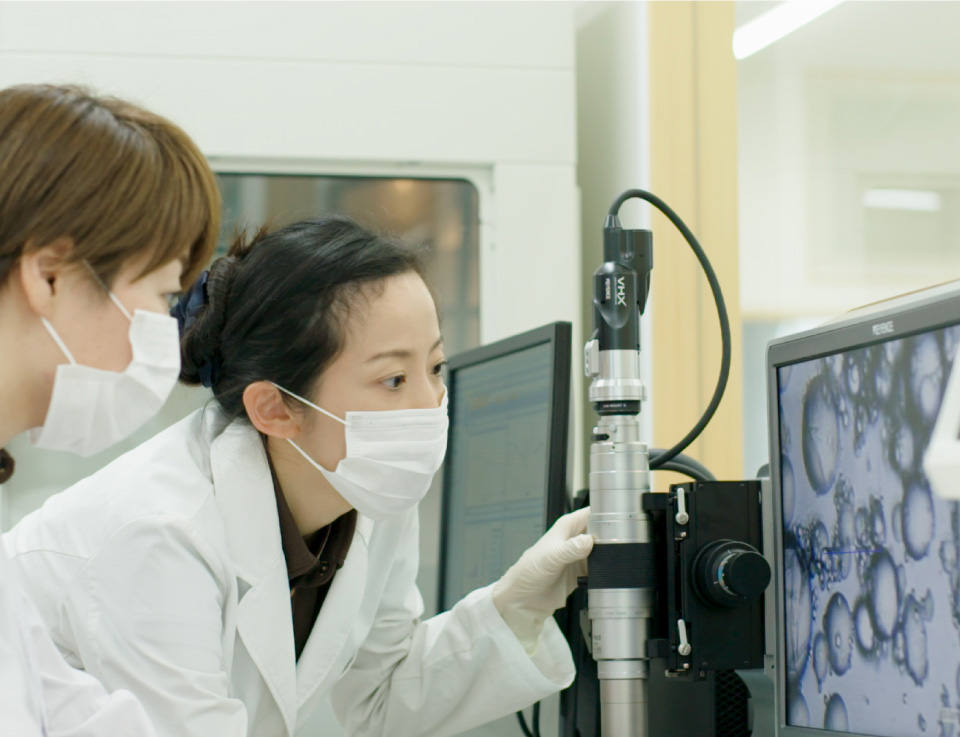

In our laboratory (testing and development lab), we conduct testing to verify the safety of cosmetics products before they are delivered to our customers as well as develop new products.

We continually conduct testing, research and development to provide safe products with superior quality to our customers.

Exterior & showroom

Exterior & showroom

Testing and development lab

Testing and development lab Manufacturing room

Manufacturing room

Packaging and shipping room

Packaging and shipping room